GREEN NITRIC ACID

Reinventing nitric acid production

Technology Overview

Arctura is pioneering a novel, scalable technology to produce green nitric acid using only air, water, and electricity. Unlike conventional nitric acid production methods that consume natural gas and emit carbon dioxide, Arctura’s technology decarbonizes nitric acid production when powered by renewable energy. This innovation will significantly reduce greenhouse gas emissions in industries such as agriculture, mining, and semiconductors. The technology enables point-of-use manufacturing, thereby cutting transportation costs and transportation-related emissions while minimizing supply chain risks.

The Challenge

The Haber-Bosch process, used to make ammonia feedstock for fertilizer and explosives, is a thermal process powered by natural gas. It feeds the growing global population, but accounts for 1-2% of worldwide energy use and emits 300 million tons of carbon dioxide annually. About 15% of the ammonia made via Haber-Bosch is used for production of nitric acid. As the world shifts away from fossil fuels, large-scale chemical production that relies on thermal processes and emits greenhouse gases should be electrified.

The Opportunity

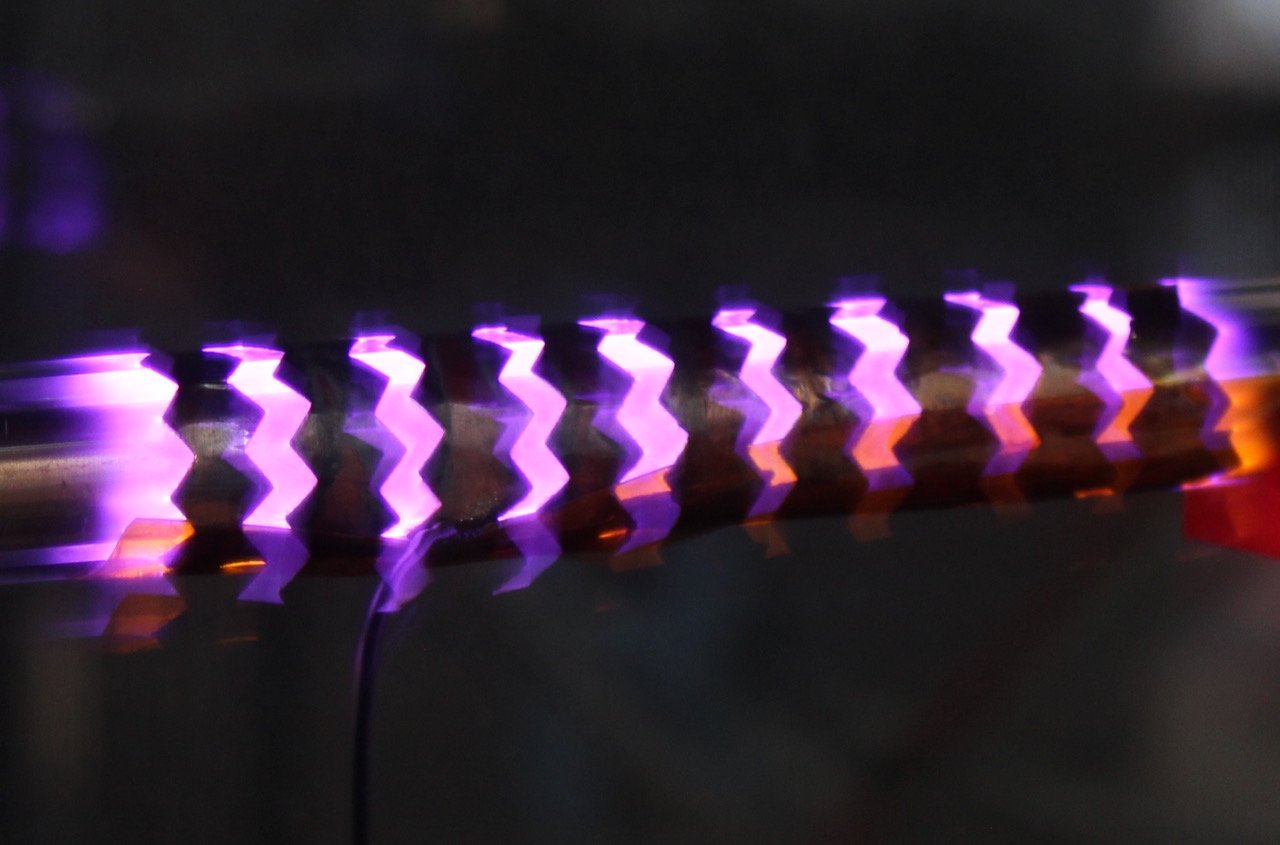

Low Temperature Plasma (LTP) processes are a viable approach to electrifying production and reducing the carbon footprint of nitric acid. Using air and electricity to generate nitrogen dioxide from plasma, and then reacting with water to make nitric acid, bypasses the Haber-Bosch process entirely. LTP can consume half the amount of energy of Haber-Bosch and eliminate carbon dioxide emissions by avoiding the use of natural gas.

Flexible and Scalable

Green nitric acid plants based on our LTP process can vary in size and be rapidly turned on and off, allowing for tailored production of concentrations and volumes of nitric acid. Decentralized, point-of-use manufacturing also benefits from avoided transportation costs, reduced supply chain risks, and lower greenhouse gas emissions.

Contact us to learn more about our plans to demonstrate and commercialize our green nitric acid technology.